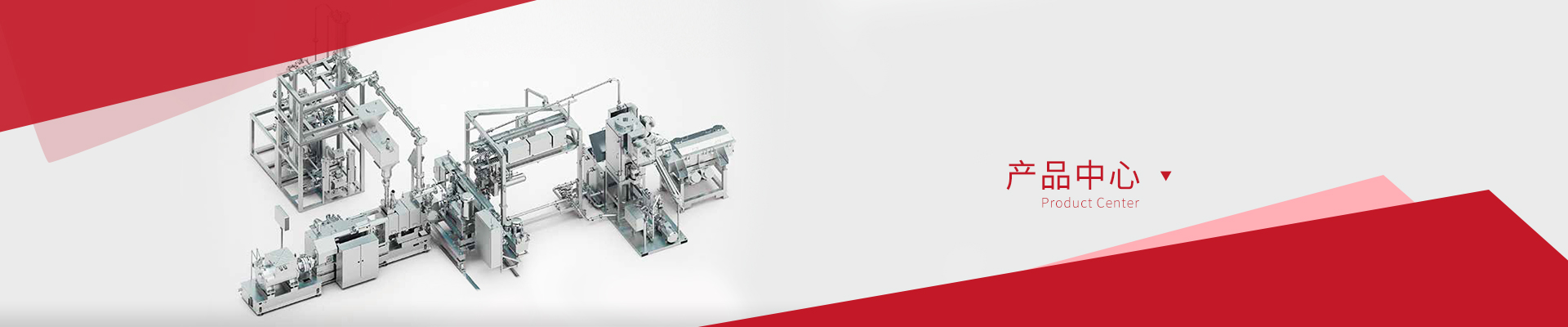

RXT series

The world's leadingCPM Extrusion Group is a leading global manufacturer and support service provider of twin screw extruders, spare parts, ancillary equipment and complete production lines

ExperiencedCPM Extrusion Group provides more than 5,000 units of equipment to partners worldwide and has extensive experience in twin-screw extruders and systems

Many resourcesCPM Extrusion Group has factories in China, USA and Germany. With rich design, project engineering, manufacturing and on-site service resources, CPM Extrusion Group is your ideal system partner

RXT series products are CPM extrusion group product designers based on the world's major mixing enterprises consistent demand, that is, high quality, high output, competitive price...... At the same time, it does not reduce the reliability, quality and service of the product. It is the first time in China to customize a cost-effective device for high-demand users.

The quality and engineering standards for the RXT series are set by CPM extrusion group engineers in the United States and Europe

RXT series products have the following characteristics:

● China, the United States, Germany jointly designed, according to the Chinese screw geometry size manufacturing

● Imported from Europe transmission box and its supporting lubrication and cooling system

● Threaded components can be matched with high standard components made in China or bimetallic materials made by the proprietary powder metallurgy process of the United States, with high wear and corrosion resistance; Special design components of German patent technology can also be selected to improve the performance of screw combination and product quality

● The mandibular shaft can be matched with high strength mandibular shaft made in China, or special cold-rolled mandibular shaft processed by the United States. The strength of the mandibular shaft is more than 35% higher than that processed by ordinary cutting technology

● Leading high - yield barrel process design

■ Proprietely hot isostatic pressing integral alloy sleeve, high wear and corrosion resistant material

■ The thickness of the cylinder is increased by 50%, which can withstand high mechanical stress

■ Cooling efficiency increased by 65%, suitable for high speed and high output of harsh operating conditions

■ Thicken and enlarge the high quality heater to ensure the heating efficiency

● High speed of screw is 900rpm

● Screw diameter from 26mm to 240mm, large selection range

● CPM global service support